How Son of a Tailor Built a Single Source of Truth for their Data with Weld

When you think of companies that have sustainability at the heart of their business model, who do you think of? Patagonia? Too Good to Go? Maybe Tesla?

In case you didn't know of them yet, there's another company that's making a name for themselves in that space – Son of a Tailor.

Son of a Tailor is a new kind of apparel company – one that's pioneering the "Made to order" model, with zero inventory waste.

In the words of Frederikke Greisen, the company's COO:

"Our end-game is to change the industry. We want the industry to move away from old habits and we want to deliver for all parties involved. We want the customers to be better off with a better fitted product, we want the garment workers to have better working conditions, and in the end we also want to save the planet by not having over production or inventory that goes to waste."

Here's how it works.

You find the t-shirt, shirt or sweater you like on their website and pop in some of your information (height, age, shoe size). Then, a tailor-made fit gets generated, the order is sent to the warehouse and production on your item starts. A few days later, it shows up at your doorstep!

This on-demand manufacturing model eliminates inventory overproduction and waste – two by-products of the traditional manufacturing model, and the main reasons why the fashion industry has such a big carbon footprint.

This model is undoubtedly revolutionary and paves the way for a more sustainable fashion industry.

The Challenge

To scale a unique business model like this one, data is essential to Son of a Tailor – for everything from their daily operations and logistics, to their customer success and marketing.

"At Son of a Tailor, data is super important. We are very reliant on knowing exactly where every single unit is. At the same time, we are reliant on capturing customer data in terms of which ads work well, and we also use customer data when we do our customer service because we want to check the history the customer has been through before before they order a new product."

- Frederikke Greisen, COO of Son of a Tailor

The problem, however, was that the company didn't have a data set-up that everyone internally could trust. That meant that the employees were doing their own analyses, there weren't many agreed upon metrics and data was living in silos.

On top of that, they "didn't have the IT resources to clean [the data] up and start from scratch", says Greisen.

The Solution

The first thing Weld did was to connect all of Son of a Tailor's sources to their own central data warehouse (BigQuery) via Weld's ETL.

This means that the customer data they collected in all of their apps – from their operations and logistics tools, to their Helpdesk, CRM and marketing tools – was streamed into a central location in real-time thanks to Weld.

Once this process was up and running, Weld's team of data analysts started working on building data models for all teams in the organization.

In the end, these data models were pushed to Son of a Tailor's BI tool (Metabase) so they could be instantly used in the company's dashboards and reports.

The Result

In a matter of two weeks, Son of a Tailor went from having silo'ed data and different metrics for every team, to a single source of data truth with robust data models that everyone in the company agreed on.

"Having this process where we could clean [the data] up, making sure that everything was correct and that everyone could trust that this was in fact the single source of truth [...] was needed."

- Frederikke Greisen, COO of Son of a Tailor

Son of a Tailor also benefitted from Weld's expert advice on cutting-edge data models, and now feels much more confident to accelerate their growth, knowing that they can trust their data and make more informed decisions with it.

Continue reading

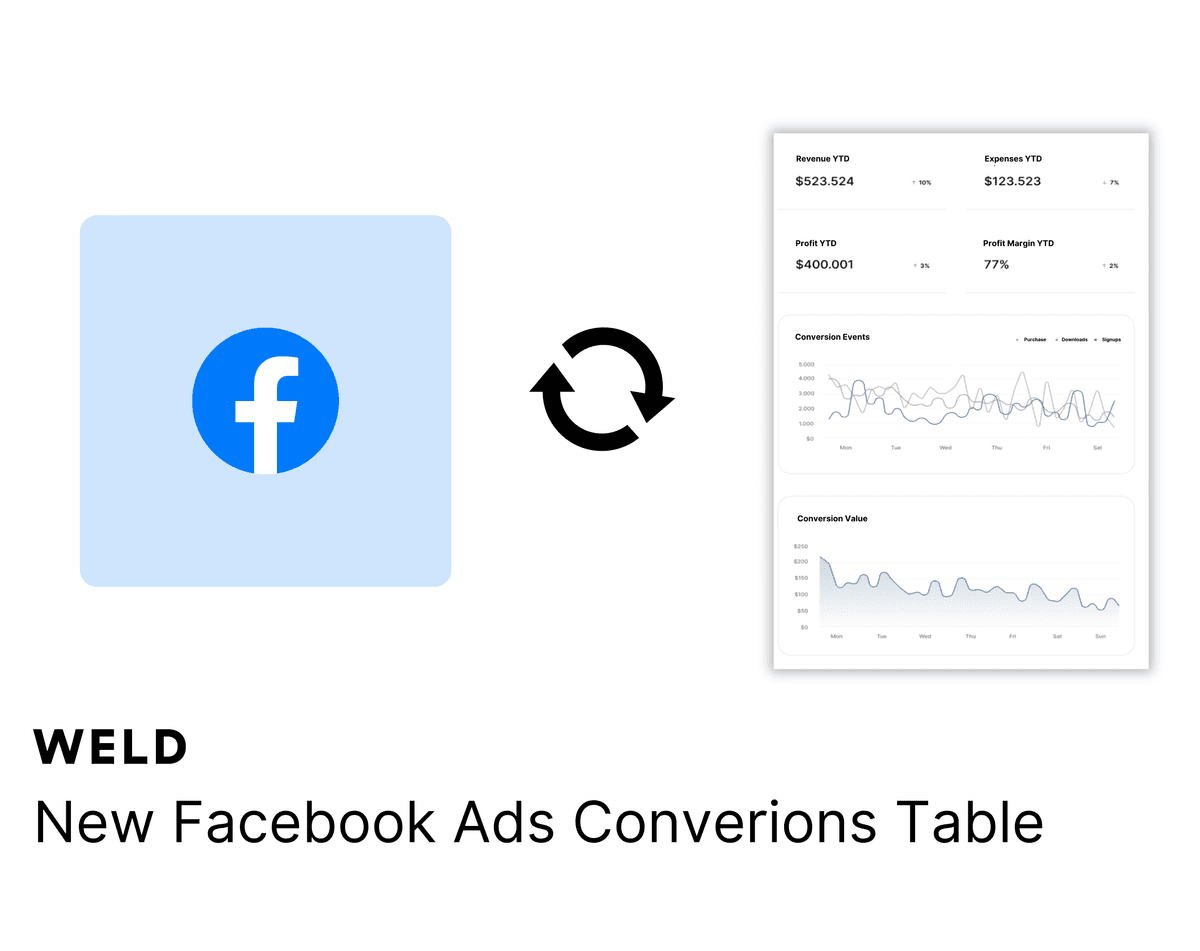

New Facebook Ads Conversion Table

Analysing your Facebook Ads conversion data has now got easier with our new conversion insights table.

New Connector Alert - Qualtrics

Need better Qualtrics reporting? Weld allows you to seamlessly integrate your Qualtrics data with the rest of data sources, creating a unified view of your business metrics. Enhance your analytics and make more informed decisions with our new ETL connector!

G2 2024 Summer Reports

The G2 2024 summer reports are live and Weld has been awarded 39 badges!